Advanced fabrication techniques for high-performance quartz components

From raw material to finished product, we maintain strict quality control at every stage

We source only the highest purity quartz materials, verified through rigorous testing

The processed quartz sand is fed into a refractory or ceramic crucible or directly into a cold crucible induction furnace

Quartz is heated to 1700–2000°C using Resistive Heating

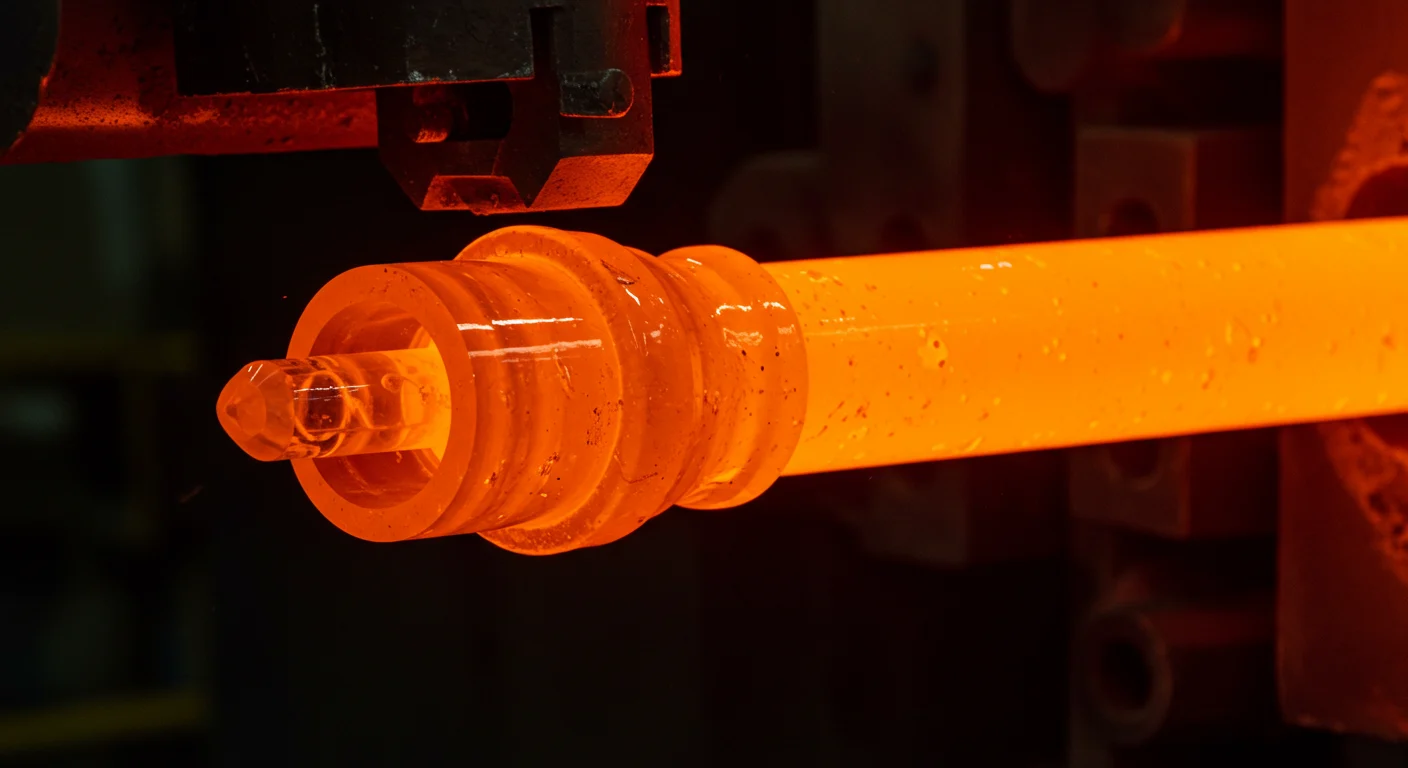

Molten quartz is drawn vertically or horizontally through dies to form long tubes or sheets

The formed quartz glass is slowly cooled in a temperature-controlled annealing oven to relieve internal thermal stresses

Comprehensive testing and verification before shipment

Quartz feed into furnace

Forming and Shaping

Polishing Station

Quality Control Lab

Every component undergoes rigorous testing to meet our exacting standards

ICP-MS analysis for metallic impurities

CMM measurement to ±0.001mm

100% component examination under magnification

Surface contamination analysis

Transmission and refractive index verification

Thermal shock and expansion coefficient testing

Contact our engineering team to learn how we can meet your specific requirements.