Advanced solutions for your most challenging manufacturing requirements

High-precision 3, 4, and 5-axis machining of complex geometries

Our advanced CNC milling capabilities deliver exceptional accuracy and surface finishes for components ranging from prototype quantities to full production runs. With 15 multi-axis machining centers, we can handle parts up to 60" in size while maintaining tolerances to ±0.0005".

Simultaneous 5-axis machining for complex contours and undercuts

Spindles to 30,000 RPM for superior finishes in aluminum and plastics

Machines with 60" x 30" x 24" travels for sizable components

Precision micro-milling for small, intricate features

Precision turning of shafts, fittings, and rotational components

Our CNC turning capabilities produce high-quality rotational components with exceptional concentricity and surface finishes. With 10 turning centers including live tooling and sub-spindle configurations, we can handle parts from 0.5" to 24" in diameter.

Live tooling for complete machining in one setup

Spindles to 4,000 RPM for superior finishes

Holding ±0.0002" on diameter for critical applications

Automated production for high-volume runs

High-precision small diameter components with complex features

Our Swiss-type CNC lathes specialize in producing small, complex parts with exceptional precision. Ideal for diameters from 0.5mm to 32mm, our Swiss machining capabilities deliver tight tolerances and superior surface finishes.

Specializing in parts from 0.5mm to 32mm diameter

Length-to-diameter ratios up to 20:1

Multiple operations in single setup

Automated bar feeding for volume runs

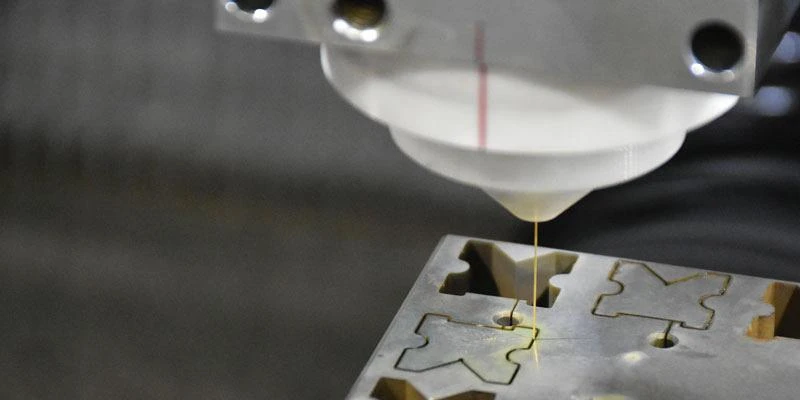

Precision electrical discharge machining for hard metals and complex geometries

Our electrical discharge machining capabilities allow us to machine complex shapes in hard metals that would be difficult or impossible with conventional methods. We offer both wire and sinker EDM services for your most challenging components.

Precision cutting of complex 2D profiles

3D cavity sinking for molds and dies

Machining hardened steels, carbides, and exotic alloys

Internal sharp corners down to 0.001" radius

Enhancing functionality and appearance of precision components

Our comprehensive surface finishing services improve both the function and appearance of precision components. From basic deburring to specialized coatings, we provide complete finishing solutions in-house.

Vibratory, tumbling, and blasting processes

Mechanical and chemical polishing options

Anodizing, plating, and passivation

Maintaining tolerances through finishing

Consistent quality from design to delivery

DFM analysis to optimize for manufacturability and cost

Recommend optimal materials for application requirements

Optimized toolpaths for efficiency and precision

Skilled machinists monitor critical operations

Comprehensive verification using CMM and metrology equipment

Careful packaging and on-time shipment